Quartz Countertop Slab Supplier

Made in Thailand, Warehouse in USA

Suitable for residential & commercial countertops

High hardness, good performance

Natual quartz stone with art visual, easy to install

Production capacity 50,000 square meters per month

Category

Model Number

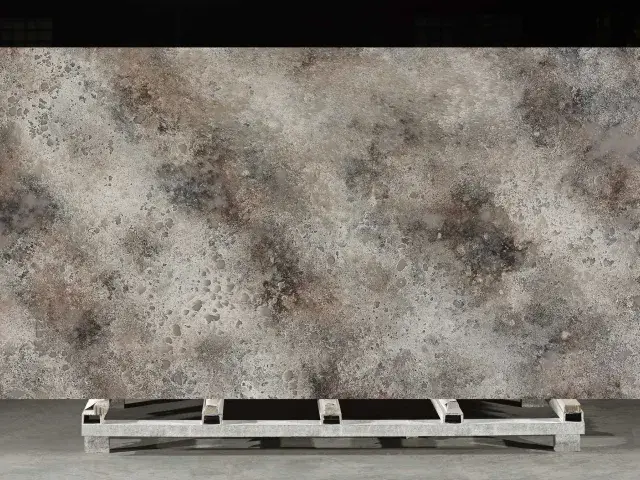

GLS048

Color

Product Speficications

Quartz Stone is a quartz-composite engineered stone which is suitable for any interior surfaces application. The product is quartz slab of Calacatta Vein.

It is a dense, non-porous stone that delivers unsurpassed reliability and performance, scratch-resistance, high stain-resistance, high heat-resistance, with no sealing required in a large variety of naturally beautiful colors.

Quartz Stone can be used for countertops, vanity tops, tub surrounds, flooring tiles, wall cladding,...etc. Standard size for pre-made countertops: 9’x2’, 9’x3’, 9’x42”, 9’x52”. Jumbo Slabs: 63”x125”.

Custom size or color can be made to complete your commercial or hotel project at very competitive price.

GL TOP Stone Co., Ltd. - Thailand Quartz Manufacturer and Exporter

- Countertop Size: 9'x2', 9'x3', 9'x42", 9'x52",

- Countertop Profile: Mitered Edge (Seamless)

- Slab Size: 122"-126"x63"

- Surface Finished: Polished

| Test Items | Test Methods | Test Results |

|---|---|---|

| Apparent Density | EN14617-1:2005 | 2340kg/mᶟ |

| Water Absorption | EN14617-1:2005 | 0.04% |

| Flexural Strength | EN14617-2:2008 | 49.9MPa |

| Thermal Shock Resistance | EN14617-6:2005 | Mass Loss: 0.03% |

| Slip Resistance (polished) | EN14231:2003 | RV "dry": 63 SRV "wet": 14 |

| Abrasion Resistance (polished) | EN14617-4:2005 | 23.8mm |

| Impact Resistance | EN14617-9:2005 | 4.38J |

| Chemical Resistance | EN14617-10:2005 | Surface finish is unaffected by the reagents |

| Linear Thermal Expansion Coefficient | EN14617-11:2005 | 28.20x10⁻⁶/⁰C |

| Mohs Hardness | EN101 | 6~7 Mohs |

| High Temp. Resistance | ASTM E84 | No cracking, no blistering |

| no color differences | ||

| Colorfastness and again test (200h) | No cracking, no crazing, no blistering, ΔΕ is 1.68 | |

| Mirror Glossiness | ASTM D523-08 | 55 |